What is a chiller?

The most important refrigeration cycles

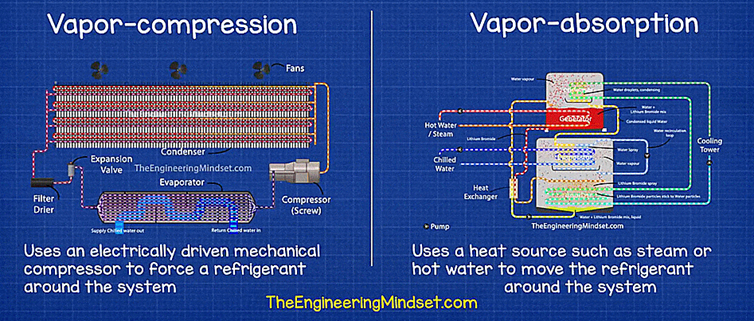

Various cycles are used to create cold, the most important of which are the compression refrigeration cycle, the absorption refrigeration cycle, and the thermoelectric refrigeration cycle.

A history of chillers

The word chiller comes from the Latin Word Chill, meaning to cool. In 1860, the first absorption chiller was built by a Frenchman named <FreudinandCar> and patented. In 1927, the first automatic absorption refrigerator entered the market under the trade name Electrolux, and the first commercial absorption chiller was sold by Carrier in 1945. In advertisements for absorption refrigerators, the title <The flame that creates cold> was used. Perhaps at that time it was a little difficult to understand that burning fuel or water vapor creates cold, but now the absorption refrigeration system is widely used due to its low electricity consumption and the absence of the use of Freon refrigerants.

With the advancement of precision manufacturing methods, it became possible to produce smaller, more efficient equipment. This, along with the availability of safe refrigerants and the invention of lower-power electric motors, made it possible to build small refrigeration units that are used today in a wide variety of applications, from home refrigerators and freezers to small air conditioners and commercial units, so that today it is rare to find a home or business that does not use one of the various types of refrigeration.

The Most Commonly Used Refrigeration Devices

Among the most commonly used refrigeration devices are absorption and compression chillers, which we briefly introduced in this post.

Compression chiller

A compression chiller performs cooling based on the compression of refrigerant gas. Compression chillers that operate using electricity have various parts such as: compressor, condenser, evaporator, expansion valve.

In this type of chiller, the gas pressure is first increased by the compressor and then enters the condenser and, by losing heat, turns into a liquid and then enters the evaporator through the expansion valve and reduces the temperature and pressure and takes the heat of the water in the vicinity of the evaporator. As a result, cooled water is produced in the chiller and is used for various purposes, including natural ventilation. In this case, the cold water passes through a closed cycle between the evaporator and the fan coil or air conditioning unit by means of a circulation pump. The condenser is also cooled by water, the heat of which is recovered in the cooling tower. Compression chillers are divided into two general groups in terms of their performance: water compression chillers and air compression chillers.

Absorption chiller

There are different types of absorption chillers, but they all work on a similar principle. In a low-pressure system, an absorbent fluid evaporates and removes heat from the cooled water. A heat source such as steam, exhaust gas, or hot water is used to regenerate the absorption solution.

In an absorption chiller, like a compression chiller, it has an absorber chamber and an evaporator for heat exchange. The absorption chiller also creates cold and reduces the temperature of the coil water by evaporation. We call it the evaporator chamber or evaporator, and we call its pump an evaporator pump or refrigerant pump.

The principle of operation of absorption and compression chillers is the same, except that a different method is used to increase the pressure of the gas exiting the evaporator for the purpose of transferring it to the condenser. After the evaporator, the water vapor is absorbed by a liquid such as lithium bromide. The absorbent liquid solution and water are transferred to the heat generator by a pump. This solution is then heated, causing the dissolved water to evaporate and enter the condenser. The rest of the cycle is the same as the compression cycle.

Waste heat from other sources can be used as a heat generator, which increases efficiency.

Absorption chillers generally have several main components: a generator, a condenser, an absorber, an evaporator, and a heat exchanger.

share :

Submit your opinion

Your email address will not be published.