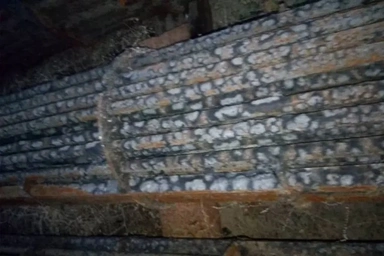

Pictures before deposition

Pictures after sediment removal

Chemical Cleaning of Reboiler 101A, South Pars 9th Refinery | Removing Multilayers of Deposits and Increasing Efficiency

In May 2020, Reboiler 101A, South Pars Gas Complex’s 9th Refinery, was facing the accumulation of complex carbonate, sulfate, hydrocarbon deposits and corrosion products after years of operation. By implementing specialized descaling operations and using scientific sampling, Abrizan Company’s technical team not only revived this vital converter, but also provided laboratory evidence that the operation was successful!

Technical Challenge: Blockage of Multilayer Reboiler 101A

Critical Situation:

- Accumulation of a complex combination of deposits in the heat exchanger:

- Carbonate deposits (caused by water hardness)

- Sulfate deposits (caused by dissolved salts)

- Corrosion products (metal oxides)

- Hydrocarbon deposits (caused by process pollutants)

- Operational Consequences:

- Severe reduction in heat transfer coefficient

- Increased energy consumption and risk of equipment failure

Smart Solution: Safe Equipment + Scientific Sampling

Preparation Phase (May 2020):

- Installation of specialized pumps and safe connections appropriate to the reboiler working pressure

- Compliance with all refinery HSE safety protocols

Innovation in Implementation:

- Continuous sampling of the scale removal solution during operation

- Immediate laboratory analysis of samples to monitor washing progress

Scientific Evidence: Analysis Results Samples

Laboratory results confirmed the removal of a large volume of sediment:

Analysis parameter | Condition before washing | Condition after washing |

Calcium carbonate concentration | Very high | Close to zero |

Sulfate concentration | Top | Standard range |

Iron particles (corrosion) | Remarkable | Complete removal |

Organic hydrocarbons | Accumulated | Complete cleaning |

These data proved the extraordinary efficiency of the scale remover solution in the comprehensive removal of all types of deposits.

Operational results: Efficiency leap after regeneration

After returning the reboiler to production:

- Significant increase in thermal efficiency (specifically recorded in the refinery's technical reports)

- Reduction in energy consumption (preliminary estimate based on operational data)

- Eliminates the need for expensive equipment replacement

- Increases the stability of performance in the production cycle

The reboiler descaling project of the 9th South Pars Refinery 101A is a model of scientific-industrial implementation in the field of equipment maintenance. The combination of professional safety equipment, documented sampling and laboratory analysis not only made the operation successful, but also provided undeniable evidence of the effectiveness of the effluent solutions. This project showed that reviving distressed heat exchangers with a scientific approach is equivalent to replacing new equipment!

Free consultation for chemical cleaning of water-circulating devices

share :