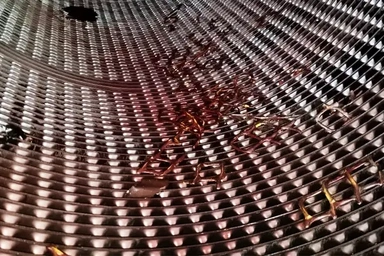

Pictures before deposition

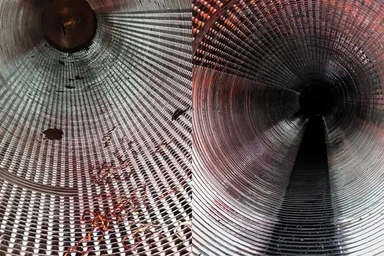

Pictures after sediment removal

Descaling of plate heat exchangers in Unit 904 of Jam Petrochemical Plant, Asaluyeh (March 1403)

Plate heat exchangers, as one of the key and sensitive equipment in the petrochemical, refining and energy industries, play a strategic role in optimizing heat exchange processes. With their innovative design based on the use of metal plates or metals such as titanium or stainless steel, these types of exchangers have outstanding advantages over traditional tubular exchangers such as higher heat transfer efficiency, significant savings in installation space and lower weight. These features have made plate exchangers an ideal choice for industries such as petrochemicals, which require precise and reliable performance under harsh operating conditions.

Necessity of Operation

In Unit 904 of Jam Petrochemical Plant, which includes part of the olefin production line, plate exchangers play a pivotal role in the heat exchange process. These exchangers are exposed to seawater and cooling water flows, which over time and due to the presence of impurities, dissolved salts and suspended particles in the water, lead to deposits on the internal surfaces of the exchanger plates. This phenomenon not only reduces thermal efficiency, but can also lead to increased pressure in the system, flow loss and even equipment failure.

With the approaching heating season and increasing ambient temperatures, the reduction in the efficiency of Unit 904 heat exchangers was raised as a serious challenge. This issue required urgent and precise measures, especially in conditions where maximum production capacity was required. For this purpose, Jam Petrochemical Engineering Unit decided to carry out chemical washing and descaling operations of the plate exchangers.

Execution of the operation

To implement this project, the technical engineering team of Abrizan Company, which has a brilliant history and deep expertise in the field of descaling of plate exchangers, shell-and-tube exchangers and thermal desalination systems, etc., was invited. The team designed and installed a suitable chemical cleaning package based on the operating conditions and technical specifications of the exchangers.

Descaling operations were performed on the E-904-G, E-904-E and E-904-H exchangers, and both sides of the exchangers (seawater and cooling water) were subjected to a chemical cleaning process. In this process, specialized chemicals and precise methods were used to remove mineral, organic and biological deposits. These materials were selected in such a way that, while effectively removing deposits, they would not damage the metal structure of the exchanger plates.

Analysis of Results and Performance Evaluation

After the operation was completed, performance data before and after chemical washing were collected and analyzed. These data included pressure drop, flow rate, inlet and outlet temperature difference, and heat transfer coefficient. The results showed that:

1. The pressure drop in the system has decreased significantly, indicating the effective removal of deposits from the exchanger plates.

2. The heat transfer coefficient has increased significantly and returned to values close to the initial conditions.

3. The water flow rate on both sides of the exchangers has improved and is close to the initial design level.

These results not only indicate the success of the chemical washing operation, but also confirm its direct impact on improving the efficiency and increasing the useful life of the exchangers.

Conclusion and Recommendations

The chemical washing and descaling project of plate exchangers of Unit 904 of Jam Petrochemical Company in Asaluyeh was successfully implemented and satisfactory results were obtained. This operation not only improved the efficiency of the exchangers, but also served as a preventive strategy in reducing the risks of failure and increased maintenance and repair costs.

In order to maintain the optimal performance of the exchangers and prevent the accumulation of deposits in the future, it is recommended that:

1. Regular planning be carried out for periodic washing of the exchangers.

2. The quality of the water entering the exchangers be continuously monitored and, if necessary, water pre-treatment systems be installed.

3. The use of protective chemicals be considered to reduce the rate of deposit formation.

This project is an example of the importance of combining technical expertise and strategic management in improving the performance of industrial equipment, which ultimately leads to increased productivity and reduced costs.

Final result: The chemical washing operation of the plate exchangers of Unit 904 of Jam Asaluyeh Petrochemical was carried out with complete success and the complete satisfaction of the company was achieved.

Free consultation for chemical washing of devices with water circulation

Free consultation for chemical washing of devices with water circulation

share :