Why do boilers experience reduced efficiency and safety hazards over time?

Introduction: Boilers, the beating heart of industry that can “have a heart attack”!

Imagine your heart not pumping blood properly — or your arteries becoming clogged with fat and plaque over time. What happens? That’s exactly what happens to boilers — the beating heart of industry.

Boilers are responsible for producing steam or hot water for industrial processes, heating buildings, sterilizing medical equipment, and even generating electricity. But over time, without regular chemical maintenance, they suffer from reduced efficiency and serious safety risks.

In this article, we’ll look at the 5 main factors that reduce boiler efficiency and safety risks:

- Scaling in boilers

- Corrosion in boilers

- Poor heat transfer

- Increased fuel consumption

- Risk of pipe explosions

And finally, we’ll provide expert solutions to prevent these risks.

Scaling in boilers: Deadly insulation on pipes

Why does scaling form?

Boiler feed water contains mineral ions such as:

- Calcium (Ca²⁺)

- Magnesium (Mg²⁺)

- Bicarbonate (₃HCO⁻)

- Silica (₂SiO)

As water evaporates at high temperatures, these ions become more concentrated and form insoluble compounds such as:

- CaCO₃(calcium carbonate)

- CaSO₄(calcium sulfate)

- Mg(OH)₂(magnesium hydroxide)

- SiO₂(silica)

which deposit as a hard, insulating layer on hot surfaces (tube walls).

Effect of Sedimentation on Boiler Efficiency

Deposit thickness (mm) | Reduced efficiency (%) | Pipe wall temperature rise (°C) |

0.5 mm | 3-5% | +15°C |

1 mm | 5-8% | +30°C |

2 mm | 10-15% | +60°C |

3 mm | 18-25% | +100°C |

Key point for boiler scaling:

Every 1 mm of scaling increases fuel consumption by 5-8%, which means higher operating costs and more emissions.

Accumulation of deposits at the bottom of the boiler after washing

Corrosion in the boiler: the hidden enemy that eats from the inside

Deposit is not the only enemy of the boiler, corrosion is a more dangerous enemy, because:

- It is invisible (until it is punctured!)

- It is sudden (cracking without warning)

- It is deadly (explosion, death of operators)

Types of corrosion in boilers:

1. Oxygen Corrosion

- Cause: Oxygen dissolved in feed water

- Symptom: Deep pitting on the pipes

- Danger: Sudden perforation → Leakage → Explosion

2. Under Deposit Corrosion

- Cause: Accumulation of oxygen and corrosive ions under the layer of deposits

- Symptom: Tiny cracks under the deposits

- Danger: Sudden failure of the pipe under pressure

3. Caustic Embrittlement

- Cause: High concentration of sodium hydroxide in areas with evaporation High

- Symptom: Branching cracks in welds

- Danger: High-temperature brittle fracture

Dangerous boiler statistics:

According to ASME (American Society of Mechanical Engineers):

- 70% of sudden boiler failures are due to subsurface corrosion.

- Every 10 minutes, a serious industrial boiler accident occurs in the world — and 40% of them result in fatalities.

Poor heat transfer: When a boiler “gets hot”!

Deposits and corrosion together cause heat transfer disturbances:

- Deposits → Thermal insulation → Reduced heat transfer

- Corrosion → Wall thinning → Increased metal temperature → Reduced strength

Effects of poor heat transfer in a boiler:

- Increase in tube wall temperature: From 300°C to 450°C

- Reduction in steam pressure: From 80 bar to 65 bar

- Water level fluctuation: Due to uneven boiling

- Buzzing or abnormal boiling: A sign of localized boiling

End result: The boiler cannot meet the required load or increases fuel consumption to meet the load.

Increased fuel consumption: invisible costs that suffocate companies

Many managers think “the boiler is working, so it’s not a problem!” But invisible costs are killing them.

Calculating the cost of increased fuel consumption:

Assume:

- Your boiler: 10 tons/h

- Sediment: 1.5mm

- Efficiency reduction: 12%

- Gas price: 5,000 riyals/m³

- Annual operating hours: 6,000 hours

Extra fuel consumption: 12% × 6,000 × base consumption = ~720,000,000 riyals/year

Extra pollution: 12% more CO₂, NOx, SOx

You can substitute your actual numbers for the hypothetical price and hypothetical annual operation.

Solution:Chemical cleaning every 18 months ← Return on investment ← Annual savings of 720 million riyals

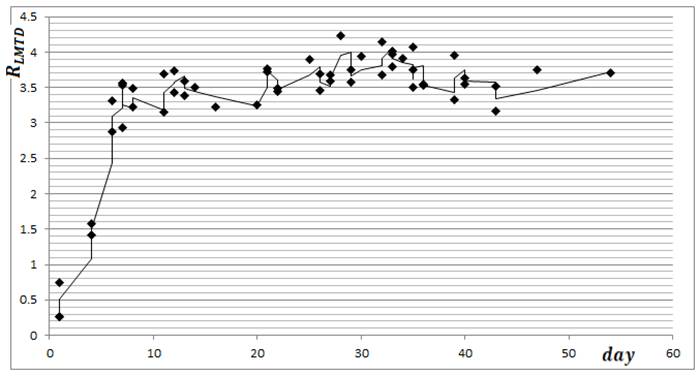

Increase in thermal resistance of deposits over time in the heating circuit

Decrease in efficiency with increasing deposit thickness

Risk of pipe explosion: Death of operators and millions of tomans in damage

The worst-case scenario for any industry is a boiler explosion and its main cause:

- Increased pipe wall temperature + decreased metal strength + internal pressure = explosion

A few real case studies:

Case 1: Textile Town — Amol Babol (2018)

- Cause: 2.5mm sediment + subsedimentary corrosion in the boiler

- Result: Boiler explosion — 5 dead and injured — huge damage

Link = 5 dead and injured due to boiler explosion in Textile Town

Case 2: Combined Cycle Power Plant — Bushehr

- Cause: Lack of periodic washing — Increased pipe temperature to 520°C

- Result: Pipe failure in turbine unit — 30-day shutdown — huge damage

Link = Pipe failure in turbine unit of combined cycle power plant — Bushehr

How to prevent explosion?

Periodic chemical cleaning (every 12-24 months)

Appropriate anti-scale and anti-corrosion injection

Continuous monitoring of temperature, pressure and water quality

Operator training to recognize warning signs

Safety standard: According to the Iranian National Standard 7999 and ASME BPVC Section VI, periodic cleaning of boilers is mandatory.

Real industrial statistics: From power plants to small factories

In this section, real statistics from various industries in Iran and the world are presented:

Table 1: Boiler failure statistics in Iran

(Costs are approximate and may vary for each time period)

Cause of failure | Percentage | Average cost of damage (million Tomans) |

Precipitation without washing | 42% | 850 |

Subsedimentary corrosion | 31% | 1200 |

No chemical injections | 18% | 600 |

Operator error | 9% | 400 |

Table 2: Savings after chemical cleaning (study on a large number of industrial boilers)

(Costs are approximate and may vary for each time period)

Index | Before washing | After washing | Improvement |

Thermal efficiency | 78% | 91% | +13% |

Fuel consumption | 1200 m³/month | 1020 m³/month | -15% |

Pipe wall temperature | 390°C | 320°C | -70°C |

Repair costs | 120 million per year | 30 million per year | -75% |

Abrizan Specialized Solutions: Prevention > Treatment

Abrizan Industrial Research Company, relying on a specialized laboratory and a professional executive team, offers comprehensive solutions:

1. Specialized chemical washing with specialized solutions

- Specialized sediment remover and anti-sediment for calcium and magnesium sulfate compounds

- Special sediment remover for removing silica deposits

- And ...

All solutions contain corrosion inhibitors without damaging metals

← Some projects carried out by Abrizan Company →

2. Injection of maintenance chemicals (Prevention)

Boiler type | Abrizan product | Application |

High pressure | Special for high pressure boilers | Anti-fouling + thermal anti-corrosion |

Medium pressure | Special for medium pressure boilers | Simultaneous control of scale and corrosion |

Hot water | Special for hot water boilers | Phosphate-free formula Eco-friendly |

Vapor phase | Special for the steam phase of boilers | Protection of steam lines and turbines |

3. Free laboratory services and consultation

- Free sediment or water sample analysis

- Specialized report + proprietary solution formula

- Application and dosing guide

Special offer:

Send us your first sediment sample — receive analysis + report + proprietary solution for free!

Frequently Asked Questions

Does scale only form in old boilers?

No! Even in new boilers, if the feed water is not suitable or maintenance chemicals are not injected, scale will form from the first week.

Does corrosion only occur in steel boilers?

No! Even in stainless steel boilers, pitting or cracking corrosion occurs if chloride or oxygen is present.

How to prevent scale formation?

- Install a reverse osmosis (RO) system for feed

- Proper anti-scale injection (such as ABR-BLR-HIPRESS)

- Continuous monitoring of feed water hardness and TDS

Request a free consultation — Free scale sample analysis

✅ Free specialized chemical consultation

✅ Free scale or boiler water sample analysis

✅ Shipping of a dedicated solution all over Iran

✅ Professional implementation at your project site

[Request free technical advice and analysis and direct contact with a sales expert]

share :

Submit your opinion

Your email address will not be published.