Proper corrosion management

Proper Corrosion Management

In general, it can be said that the corrosion process will never stop, but it can be controlled to a large extent by implementing a corrosion management program. In fact, by implementing corrosion management, organizations can proactively plan to improve the design, operation, and maintenance of their critical assets, and as a result, reduce the cost of controlling unexpected damage and failures caused by corrosion.

Corrosion Management Plan:

The Corrosion Management Plan (CMP) is part of the overall facility management system that is related to the development, implementation, review, and maintenance of the principles of the corrosion process. Corrosion management deals with the management of threats to mechanical integrity caused by various mechanisms of deterioration, corrosion, and material failure. The most common approach to improving corrosion management of equipment and assets is to conduct an integrity review and use its various products to create or update a corrosion management strategy document.

Benefits of CMP

- Identifying corrosion threats

- Investigating critical corrosion challenges

- Assessing risk

- Improving operational processes (nuclear, strategic, tactical, and atomic)

- Implementing corrosion control and mitigation strategies

- Implementing corrosion monitoring and inspections

- Equipment integrity

- Monitoring and managing equipment performance

Between the sources of hydrocarbons and the places where they are used as fuel, there is a vast network of oil and gas industry infrastructure. The oil and gas industry includes production, transmission, storage, refining, and distribution sectors. Failure in any of these units negatively impacts not only the performance of that sector, but also downstream sectors. This means that the infrastructure of the oil and gas industry is continuously interdependent. For example, a failure (failure) in one production sector may affect the downstream pipeline and refinery sectors.

Corrosion Integrity Management:

Integrity management ensures that all assets and pipelines operate effectively and efficiently throughout their designed lifespan. Integrity management may also be known as Asset Integrity Management (AIM) and Pipeline Integrity Management (PIM) when applied to assets and pipelines, respectively. Implementing the integrity management process requires an assessment of all risks. One of the hazards of oil and gas infrastructure is corrosion. Therefore, reducing the risk of corrosion is a key component of integrity management.

Corrosion Damage:

The annual cost of corrosion in the US oil and gas industry is over $27 billion, leading some to estimate the global annual cost of corrosion in the oil and gas industry to be over $60 billion. For companies with oil or gas infrastructure, the need to reduce the costs associated with corrosion is essential. The oil and gas industry is striving to reduce the probability of failure due to corrosion to zero. Achieving this goal requires the integration of several activities that take place at different stages, including design, construction, commissioning, operation, and maintenance.

Effective leadership and appropriate management tools must be in place to coordinate and integrate the activities carried out at different stages. These activities may be carried out by the following individuals:

- Oil and gas infrastructure designers

- Engineers responsible for oil and gas equipment and infrastructure

- Workforce trainers and coaches

- Construction and maintenance supervisors working in plants and rigs

- Consultants who recommend, develop and implement corrosion control strategies

- Engineers who inspect equipment and infrastructure

- Research and development practitioners who develop new knowledge and insights

The following discusses some of the common management tools including the 5-M methodology, risk-based inspection (RBI) and direct assessment (DA) for corrosion control in the oil and gas industry.

Corrosion Control Tools in the Oil and Gas Industry:

5-M Methodology

Corrosion is a natural phenomenon that cannot be avoided or prevented. However, with the right strategies and tools, it can be controlled so that the thickness of the material used exceeds the reduced thickness due to corrosion over the design life of the equipment. The keys to effective and economical corrosion control are as follows:

- Better assessment of corrosion risks

- Selection of cost-effective methods for corrosion mitigation

- Quantitative measurement, estimation, and monitoring of corrosion rates and/or inspection of remaining wall thickness at regular intervals

- Maintenance of oil and gas infrastructure on a continuous basis so that changes to the corrosion management program in one department do not affect other departments downstream.

- Integration of top-down and bottom-up approaches

- Better understanding of the fundamentals of corrosion control practices and standards

The 5-M methodology integrates all of the key activities mentioned above.

Components of the 5-M Methodology

The 5-M methodology consists of five distinct components: modeling, mitigation, monitoring, maintenance, and management:

Modeling:

The primary function of modeling is to predict the susceptibility or insensitivity of a given material to a particular type of corrosion (corrosion damage mechanisms (CDM)) in a given environment, and also to estimate the corrosion rate of the material in that given environment.

Mitigation:

The goal of mitigation is to develop mitigation strategies if the modeling predicts that the corrosion rate is high, i.e. at this corrosion rate the minimum material thickness used as the allowable corrosion value is insufficient.

Monitoring:

The goal of monitoring is to ensure that the pipeline is performing in the manner predicted by the model and that mitigation strategies are adequate.

Maintenance:

All of these strategies will fail if good maintenance strategies are not developed and implemented.

Management:

Corrosion management integrates corrosion control strategies (modeling, mitigation, monitoring, and maintenance) with the implementation of overall integrity management operations.

Implementing the 5-M Methodology

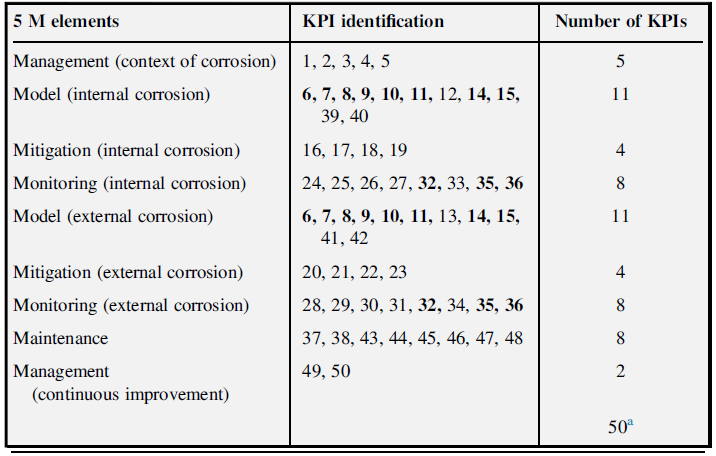

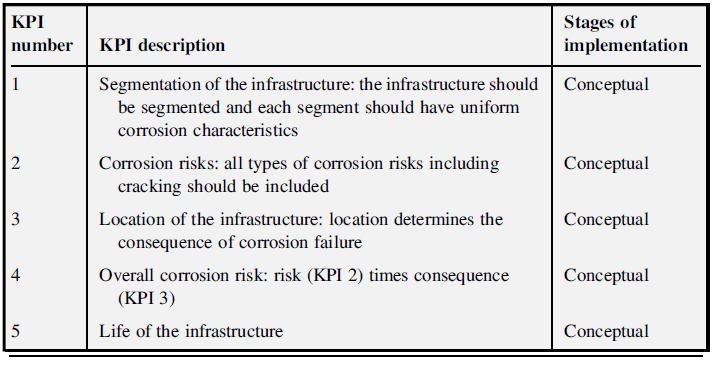

All five elements must be implemented for effective corrosion control in the oil and gas industry. To facilitate the implementation of the 5-M methodology, the establishment of key performance indicators (KPIs) is required. Industry surveys and failure analysis have identified 50 key performance indicators (KPIs), which are shown in Table 1.

Table 1 - Key Performance Indicators (KPI) for Effective and Economical Implementation of Corrosion Control Strategies

Management – Corrosion Control Context

Not all units are created equal from a corrosion perspective. Corrosion may be negligible in one unit, while it may be considered hazardous in another. For example, corrosion control in a sweet gas pipeline operating in a remote area may not be as important as in a sour gas pipeline operating in a densely populated area. Therefore, it is important to manage corrosion by establishing a “corrosion control context.” The corrosion control context is established using five (5) KPIs. Table 2 outlines these KPIs and the steps to implement them.

Table 2_ Characteristics of Key Performance Indicators (KPIs) for establishing a corrosion control framework

Modeling - Internal Corrosion

Modeling is a roadmap or guideline to show the rate of material loss over time due to internal corrosion. Nine (9) KPIs are used to predict internal corrosion, as presented in Table

Table 3_ Characteristics of Key Performance Indicators (KPI) for Internal Corrosion Modeling

Mitigation – Internal Corrosion

If the model indicates that the thickness loss due to corrosion exceeds the allowable corrosion limit over the design life of the infrastructure, corrosion mitigation strategies should be adopted. Four (4) KPIs are used to implement mitigation strategies as shown in Table 4.

Table 4_ Characteristics of Key Performance Indicators (KPIs) for reducing internal corrosion

It is worth mentioning that these KPIs are also determined for external corrosion in each strategy of this methodology, as well as for internal corrosion, and are available in scientific sources.

Scoring of key performance indicators

The implementation status of each KPI can be shown with color indicators or scores, or both (Table 5). By summing the KPI scores, an “overall score” can be determined. Assuming that the maximum score for all KPIs is 5, the maximum possible overall score is 250. Based on the overall score and the maximum overall score, the percentage score for corrosion and corrosion control is calculated. For example, if the overall score for an asset is 50, the corrosion control score is 80 percent and the corrosion score is 20 percent.

Table 5_ Scoring of key performance indicators

For example, a case study evaluated the application of these fifty KPIs to implementing effective corrosion control in oil and gas pipelines.

The pipeline under study was constructed in 1975 and commissioned in 1976 to transport condensate, sweet and sour crude oil from Western Canada from Sarnia to Montreal. The minimum wall thickness of the carbon steel pipeline was 6.35 mm. Figure 1 shows the implementation status of the fifty KPIs in this pipeline. Overall, the pipeline is in safe and reliable operating condition from a corrosion perspective. Further management oversight would further enhance the integrity of the pipeline.

Figure 1_ Implementation status of 50 key performance indicators in the oil pipeline.

Risk-Based Inspection (RBI)

RBI is a process for understanding the likelihood of a hazard and its consequences. It identifies all hazards, including corrosion, risk-increasing factors, and the stage each asset is in (commissioning, operation, or beyond design life). The product of risk and consequences is scored using a matrix system, and an overall risk score is determined (Figure 2). Based on the risk score, the inspection schedule and frequency are prioritized, and cost-effective solutions to mitigate the risk (e.g., repair or replacement) are developed.

Figure 2_ Risk quantification

The RBI process significantly reduces the number of locations that need to be inspected, meaning that inspections are only performed on high-risk equipment and no inspections are performed on low-risk equipment. This process therefore significantly reduces the cost of corrosion control without increasing risk.

The RBI process is not only applicable to refinery equipment and piping, but can also be used for any type of asset in the oil and gas industry.

Direct Assessment (DA)

In a way, the principle of the Direct Assessment (DA) process is similar to the RBI process. In both processes, the areas with the highest risk are identified and attention (mainly inspection) is focused on the areas with the highest risk. The DA process was developed primarily for oil and gas pipelines that cannot be inspected internally using in-line inspection technology.

The DA process can be used to assess internal corrosion, external corrosion, and external stress cracking. All DA processes have four stages:

1. Pre-assessment: In this stage, all relevant, historical, necessary and current data are collected to determine the feasibility of carrying out the DA process. If the data is insufficient, the DA process cannot be carried out.

2. Indirect inspection: In this stage, the data collected is used to predict the overall severity of failure of different sections of the pipeline. This stage also involves segmenting the pipeline according to its operating conditions and surface characteristics. Based on the analysis, corrosion-prone locations in the pipelines are identified.

3. Direct inspection: In this stage, locations that are predicted to have a higher corrosion risk (in stage 2) are non-destructively inspected.

4. Post-assessment: In this stage, all data collected in stages 1 to 3 are analyzed to prioritize mitigation, maintenance or repair strategies. The next inspection date is also determined in this stage.

Current status and future development of corrosion management

Today, regulatory, public, environmental and media attention to the oil and gas industry is at a higher level. In general, it is important not only to keep the risk from corrosion low, but also to demonstrate that the risk is being kept low. To achieve this goal, the importance of corrosion management is growing increasingly. It is essential that the oil and gas industry continues to use corrosion control management tools and gradually improve them. Up-to-date and modern technologies for progress in this field (e.g., online training courses) are available and are being used. It is expected that the use of modern technologies in the implementation of management tools will continue to grow.

share :

Submit your opinion

Your email address will not be published.