Guide to annual maintenance of heating systems with specialized chemicals

Annual maintenance of heating systems with specialized chemicals

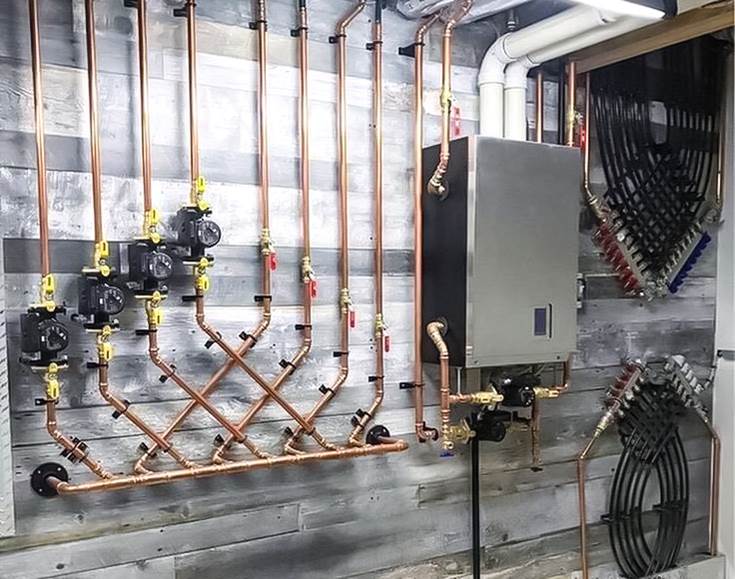

Is your heating system experiencing pressure drops, unusual noises, or inadequate heating after each winter season? These problems are usually caused by a lack of ongoing chemical maintenance — not equipment failure. Annual maintenance with specialized chemicals not only extends the life of the system by 2 to 3 times, but also reduces energy consumption by up to 20%. In this guide, we will teach you step by step how to implement a smart maintenance program, season by season, tailored to your system type.

Why does your heating system fail without chemical maintenance?

Many people think that if the system is “working”, there is no need for intervention. But behind this appearance, three hidden factors gradually destroy the equipment:

1. Scale — from the accumulation of water salts on hot surfaces (exchangers, boiler walls)

2. Corrosion — especially in dead spots or long shutdown times

3. Foam and gas — caused by dissolved oxygen or improper chemical reactions

These factors lead to reduced heat transfer, increased pressure, temperature fluctuations and, ultimately, pump failure or burst pipes.

Three main components of an effective chemical maintenance program

For a successful maintenance program, “just one bottle of antifreeze” is not enough. You need an integrated system:

1. Annual analysis of circulating water

- Check pH (should be between 8.5 and 10)

- Measurement of total hardness and calcium/magnesium ions

- Determination of dissolved oxygen concentration

- Identification of sulfate-reducing bacteria (in semi-open systems)

2. Inject or top up with protective chemicals

Chemicals degrade after 6 to 12 months. Even in shut-down systems, corrosion processes continue. Therefore, restore the surface of the materials every year before the heating season.

3. Periodic chemical flushing (every 2–3 years)

If the system has not been flushed for more than two years or if there are signs of pressure loss, use a mild, non-acidic descaling agent. This should be done by a professional to avoid damaging the metals.

Seasonal planning: What to do each season?

Spring: End of heating season — time to evaluate

- Shut down the system

- Take a sample of circulating water

- Perform an initial flush if necessary

Summer: Ideal time for maintenance

Because the system is resting, you can:

- Perform chemical flushing

- Inject protective agents

- Check sensors and expansion vessel

This is essential for villas, hotels and resorts in cold climates.

Autumn: Prepare for winter

- Check antifreeze and anti-boiler levels

- Top up anti-corrosion and anti-foaming agents

- Adjust system pressure and expansion vessel volume

Winter: Active monitoring

- Check outlet pressure and temperature weekly

- Pay attention to the sound of pumps

- Take any sudden changes seriously

Four essential chemicals for every heating system

1. Multi-metal corrosion protection

Heating systems usually include copper, steel, cast iron and aluminum. An effective formulation must protect all of these metals simultaneously — not just one.

2. Combined antifreeze and anti-boiler

This product not only lowers the freezing temperature (for example, to -48 ° C), but also raises the boiling point of water (up to + 120 ° C). This feature is very important for industrial engine rooms in the summer.

3. Antifoam

Scum reduces pump efficiency, pressure fluctuations and errors in temperature sensors. In systems with fast flow or open expansion sources, the use of antifoam is essential.

4. Biocide (for semi-open systems)

In cooling towers or open expansion sources, the growth of bacteria and algae is inevitable. The use of oxidizing or non-oxidizing biocides prevents the formation of biofilm and microbial corrosion.

When do you need laboratory analysis?

Warning signs

- Red circulating water (iron rust)

- Black water (iron sulfide or biofilm)

- Cloddy water or with suspended sediment

Pressure drop or pump roaring sound

How is the type of problem diagnosed?

Specialized laboratories use methods such as:

- XRD (deposition type identification: carbonate, sulfate, silica)

- SEM/EDS (corrosion surface analysis)

- Chemical tests (ion concentration, bacteria)

to diagnose the exact type of problem and provide a customized solution.

Why is a “standard” formulation not enough?

Each region’s water has a different ionic composition. A formulation that works in Tehran may cause corrosion in Tabriz. The best solution is to use customized chemicals based on local water analysis.

❓❓❓ Frequently Asked Questions (and Practical Answers) ❓❓❓

❓ Do new systems also require chemical maintenance?

Yes. Even new systems are susceptible to immediate corrosion (especially in copper-steel connections). Protection from the start is to prevent hidden damage.

❓ What is the difference between general and specialized anti-corrosion?

General anti-corrosion is effective only on one type of metal. Specialized formulations are designed for multi-metal systems and are also anti-scale and anti-foam.

❓ Can I do the chemical cleaning myself?

In small domestic systems (such as villa packages), it is possible by following the instructions and using non-acidic materials. However, in large industrial systems or engine rooms, it is recommended to have this done by a specialist. (Introducing Mitreh Antifreeze)

❓ How much does annual maintenance cost?

The annual maintenance cost is usually less than 5% of the cost of replacing a pump or exchanger, but it can prevent breakdowns that are 10 to 20 times more expensive.

Conclusion: Annual maintenance is not a cost, it is a smart thing

Regular chemical maintenance is the only way to prevent unexpected breakdowns, reduce energy consumption and extend the life of equipment. With a simple seasonal schedule and the use of the right materials, you can keep your heating system trouble-free for years.

If you are not sure about the type of your system (domestic, industrial, automotive) or the quality of your local water, start with a professional analysis. This small task can prevent thousands of dollars in repair costs.

If you need expert advice to identify the type of scale or the optimal selection of chemicals, Abrizan Company specialists, with more than 20 years of experience in advanced laboratories, are ready to provide customized solutions to various industries.

share :

Submit your opinion

Your email address will not be published.