Fire Tube Boilers

Introduction: What is a Boiler and Why is Fire Tube Important?

A Boiler is one of the main components in the energy production, refining, power plant and thermal process industries. This equipment converts water into steam using fuel (gas, oil, biomass) and the steam produced is used in various processes such as electricity generation, heating, drying and distillation.

Among the types of boilers, Fire Tube boilers are very common in small and medium-sized industries due to their simple design, lower cost and quick start-up.

In this article, we will comprehensively review Fire Tube Boilers, from working principles to types, advantages, disadvantages, service life, maintenance and solutions to prevent scale and corrosion — all with a practical approach based on industry standards.

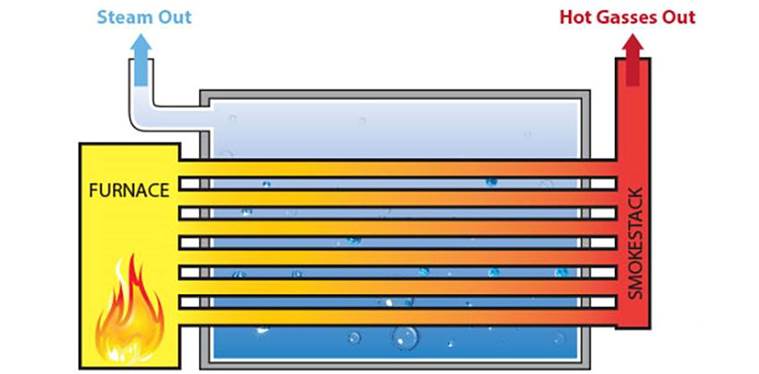

What is a Fire Tube Boiler? (Definition and working principle)

In a Fire Tube Boiler, the flame and hot gases (combustion products) pass through tubes that are located inside a large water tank. The heat of these tubes is transferred to the surrounding water, causing the water to evaporate and produce steam. (How do fire tube boilers work?)

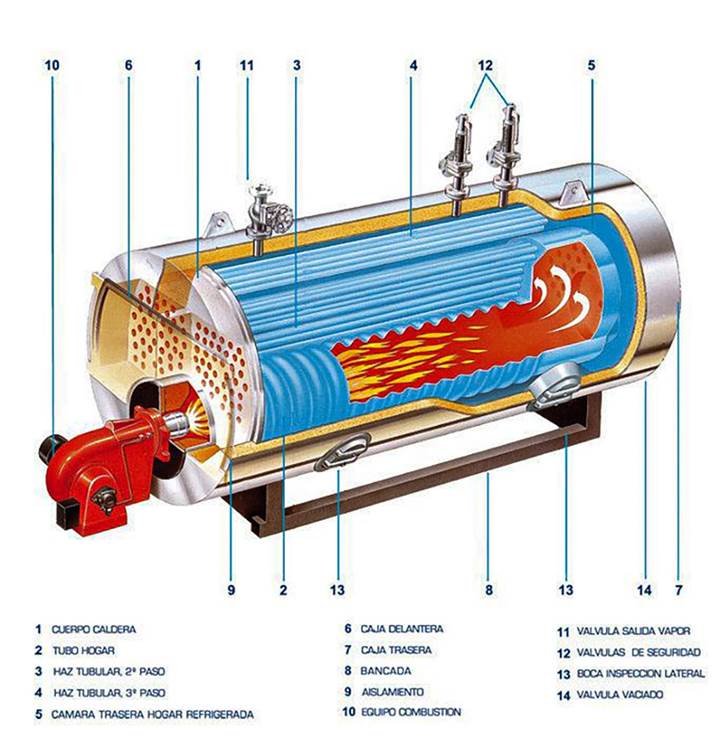

The main structure of a fire tube boiler

- Burner: Creates the flame

- Fire Tubes: Passes the hot gases

- Shell: Contains water around the tubes

- Damper: Adjusts the flue

- Control and safety system

Difference between Fire Tube and Water Tube Boilers:

Feature | Fire Tube | Water Tube |

Flow direction | Hot gas in the pipe, water out | Water in the pipe, gas out |

Working pressure | Usually up to 25 bar | Up to 300 bar and above |

Capacity | Small to medium (up to 25 tons/hour) | Very large |

Application | Small industries, heating | Power plants, large refineries |

Types of Fire Tube Boilers

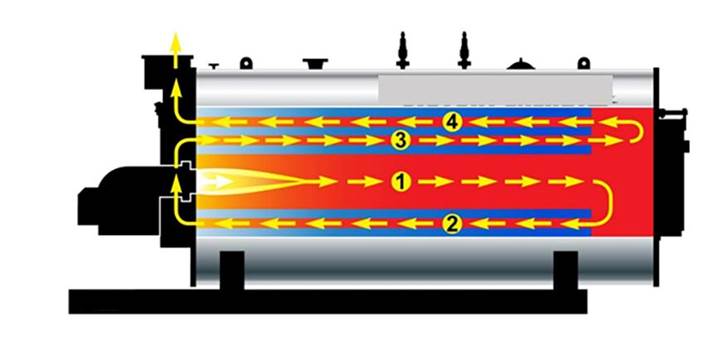

Four-Pass Fire Tube Boiler

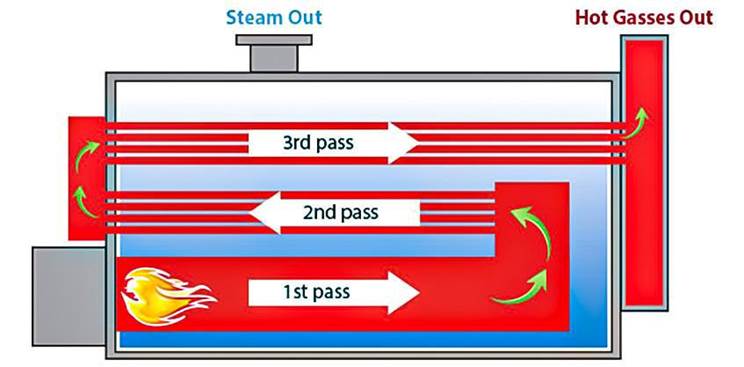

Three-Pass Fire Tube Boiler

- Hot gas passes through the tubes in three stages.

- Higher efficiency (up to 85-90%)

- Most common type in industries

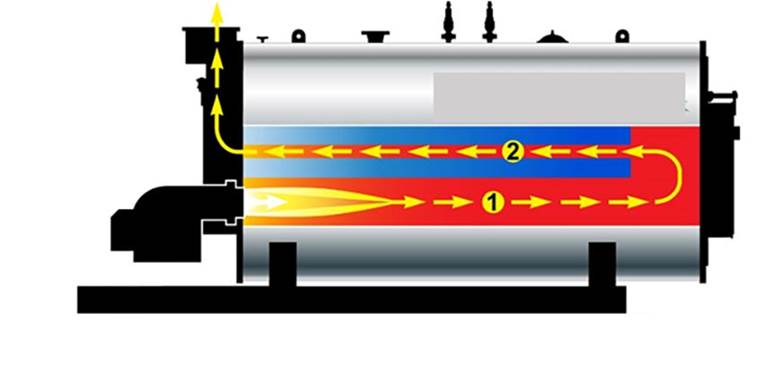

Two-Pass Fire Tube Boiler

- Simpler and cheaper

- Lower efficiency

- Suitable for small needs

Single-Pass Fire Tube Boiler

- Lowest efficiency

- Only used in special cases

Package Boiler

- All equipment installed in one package

- Quick installation and commissioning

- Suitable for semi-fluid industries

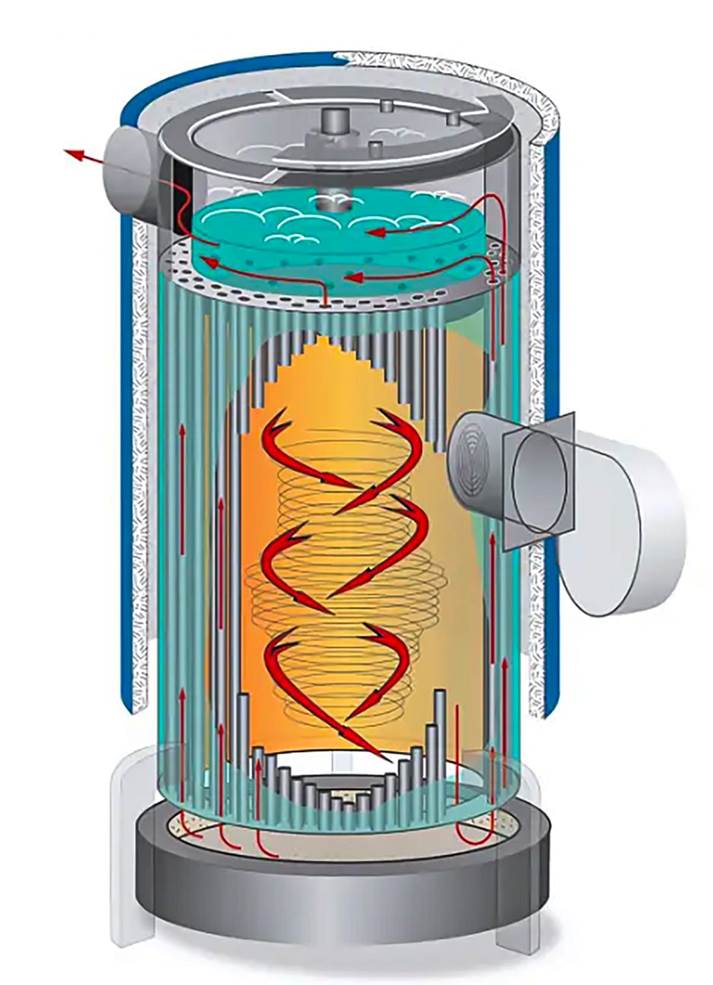

Vertical Fire Tube Boiler

- Small footprint

- Low capacity

- For small applications (e.g. steamers)

Advantages of Fire Tube Boilers

✅Fast installation and commissioning

✅Lower initial cost

✅Less space requirement

✅Easy control and high safety

✅Less manpower requirement

✅High resistance to pressure fluctuations

✅Ability to produce wet steam with acceptable quality

These advantages have made Fire Tube Boilers very popular in the food, textile, manufacturing, hospitals and heating systems industries.

Disadvantages and limitations of Fire Tube Boilers

❌Limited capacity (usually up to 25 tons of steam per hour)

❌Low working pressure (not suitable for large power plants)

❌Longer time to reach working pressure (due to high water volume)

❌Sensitivity to water quality (formation of deposits in pipes)

❌Risk of explosion in case of failure of the main tank (Shell)

❌Limited access to the inside of the pipes for cleaning

These disadvantages show that regular maintenance and prevention of deposits play a vital role in the life and safety of the device.

Fire Tube Boiler Lifespan The lifespan of a Fire Tube Boiler depends on the following factors:

Agent | Impact |

Feed water quality | Low quality→sediment→reduced life |

Maintenance plan | No washing→corrosion and cracking |

Fuel type | Improper fuel→soot and ash |

Environmental conditions | High humidity→external corrosion |

Build quality | Use of low quality steel→cracks |

Average life:

- Without proper maintenance: 8 to 12 years

- With periodic maintenance: 15 to 20 years

- With preventive maintenance and chemical washing: up to 25 years

Scaling formation in Fire Tube Boilers and its consequences

How is scale formed?

The feed water contains calcium, magnesium, bicarbonate and silica. With increasing temperature, these substances precipitate as calcium carbonate, calcium sulfate and silicate.

Consequences of scale formation:

- Reduced heat transfer (scaling is a thermal insulator)

- Increased fuel consumption

- Increased tube temperature and risk of cracking

- Reduced steam production

- Under Deposit Corrosion

Fire Tube Boiler Maintenance and Chemical Cleaning

Pre-treatment of feed water

- Water Softener

- Reverse Osmosis (RO)

- Dosing of chemicals (anti-scalant, oxygen scavenger)

Periodic Blowdown

- Partial discharge of water to reduce solids concentration

Chemical Cleaning

- Use of anti-scaling solutions to remove deposits

- Periodically (every 6 to 18 months)

- Prevent reduction in efficiency

Basic descaling

- In cases where the pipe space is more than 30% blocked

- Use of non-acidic solutions with anti-corrosion properties

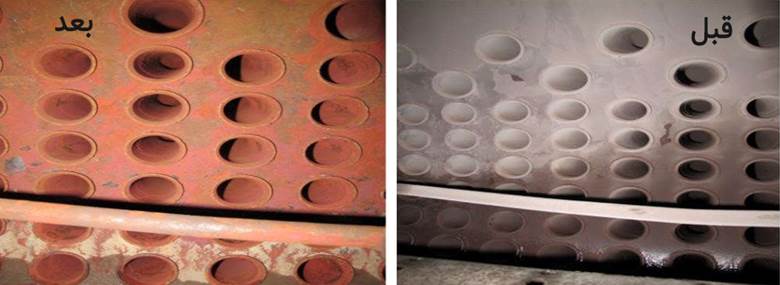

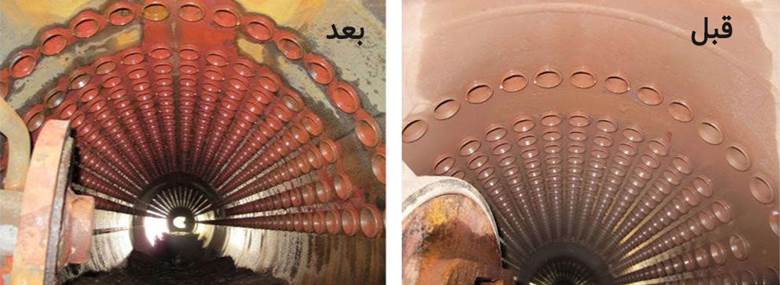

Case Study: Chemical Cleaning with Mitreh

- Specialized cleaning of boilers at Fajr Jam Gas Refinery with Mitreh solution

- Fire Tube boiler with severe efficiency loss

- After cleaning with Mitreh solution by Abrizan's expert team:

- 7% increase in boiler efficiency

- Fuel consumption decreased

- Increased steam production without worrying about blockage or corrosion

- No secondary damage or corrosion

- Full satisfaction of the Fajr Jam Refinery's technical and management team

Fire Tube Boiler Maintenance Safety Tips

- Never enter the tank without depressurizing and completely shutting down.

- Use breathing apparatus and eye protection.

- Protect all sensors and valves before chemical cleaning.

- Cleaning solutions must be non-corrosive and fully washable.

- After cleaning, a thorough water rinse is essential.

Why is it important to choose the right cleaning solution?

Using inappropriate solutions can:

- Cause corrosion

- Cause cracks in the steel

- Create new deposits

Characteristics of an ideal cleaning solution:

- Non-acidic (to prevent corrosion)

- Contains anti-corrosion agents

- Capable of dissolving carbonates, sulfates and silicates

- Fully washable without residue

✅Mitreh products with specialized formulations meet these conditions and have proven their effectiveness in hundreds of industrial projects.

Summary and Operational Recommendations

- Fire Tube Boilers are an ideal option for small and medium-sized industries.

- Periodic maintenance is the key to increasing life and efficiency.

- Chemical flushing with specialized solutions (such as Mitreh) can improve efficiency by up to 30%.

- Using a specialized team to perform the operation is essential.

- Feedwater pretreatment is the first step to prevent fouling.

Credible Sources

1. ASME Boiler and Pressure Vessel Code (BPVC)

2. API Standard 560 – Fired Heaters for General Refinery Services

3. NACE SP0106 – Control of Corrosion in Boilers

4. U.S. Department of Energy – Boiler Efficiency Guidelines

5. ScienceDirect: "Fouling in Fire Tube Boilers: Causes and Prevention"

6. Abrizan Industrial Research Company Reports – Projects Completed with Mitreh Solution

share :

Submit your opinion

Your email address will not be published.