Investigating the phenomenon of corrosion in the cooling tower and its control

Corrosion in a cooling tower

Corrosion is one of the most important problems in a cooling tower and causes cost loss and reduced tower efficiency. The presence of various factors in the tower makes it easy for corrosion to occur in a cooling tower. The presence of water as an electrolyte and the presence of different metals in the tower as cathodes and anodes provide the basis for creating a large-scale chemical cell! The presence of water in the tower and temperature changes accelerate the corrosion process.

Deposits and corrosion due to migration of electrons

In the cooling tower, various impurities and changes in pH, we are practically faced with oxidation-reduction reactions. The migration of electrons from the anode to the cathode causes the gradual destruction of the anode and the formation of deposits on the metals, which in turn accelerates corrosion. Corrosion in the cooling tower is usually observed in the form of pits and grooves. To prevent the occurrence and development of corrosion, it is enough to disconnect at least one of the three elements of the chemical cell, namely the anode, cathode and electrolyte.

Anti-Corrosion Solutions in Cooling Towers

To prevent corrosion in cooling towers, we use substances called corrosion inhibitors. These inhibitors create a protective layer on the metal, preventing it from reaching the electrolyte and stopping or slowing down corrosion.

The following reaction occurs at the anode:

Fe → Fe2++2e– (1)

The following two reactions occur at the cathode:

H2O+1 ∕ 2O2+2e– → 2OH– (2)

2H++2e– → H2 (3)

The following reactions also take place:

Fe2++2OH– → Fe(OH)2 (4)

2Fe(OH)2+1 ∕ 2 O2+H2O → 2Fe(OH)3 (5)

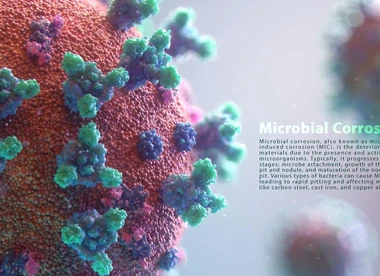

The situation is further worsened by the formation of deposits on the metal, and a sludge consisting of microorganisms forms on the metal, creating an aerobic condition in contact with the metal, which causes the formation of sulfur compounds:

SO42- +10H++8e– → H2S+H2O (6)

Factors affecting the corrosion rate

Among the most important factors that accelerate the corrosion process in the tower are:

- pH:pH is almost constant between 6.5 and 9.

- Calcium hardness:For water with high calcium hardness, the amount of corrosion inhibitor decreases and vice versa.

- Accumulation of aggressive ions:Among the aggressive ions are chloride ions and sulfate ions, which in high concentrations attack the protective layer created by the inhibitor and weaken or destroy it.4)

- Water velocity:The higher the water velocity, the higher the corrosion rate, but on the other hand, with the presence of a corrosion inhibitor, the higher the water velocity, the better and greater its effect will be. Therefore, it is always necessary to work at an optimal water velocity.

Source: Investigation of the two phenomena of sedimentation and corrosion in a cooling tower and its control in an industrial case study

share :

Submit your opinion

Your email address will not be published.