History of corrosion and scientific approach to corrosion

Introduction: Why is corrosion the invisible enemy of industry?

Imagine an industrial boiler that has been operating without problems for years, suddenly its efficiency decreases, its fuel consumption increases and finally leaks. The reason? Invisible corrosion that has been going on for years in the heart of metals and is now showing its devastating results.

Corrosion is not just a chemical phenomenon; it is also an economic, safety and performance challenge in various industries. Every year billions of dollars are wasted due to corrosion-related damage worldwide. But the good news is that corrosion can be controlled — provided that scientific principles and up-to-date solutions are used.

In this article, while reviewing the scientific history of corrosion, we will discuss practical, experimental and applied solutions to combat it in industrial equipment such as boilers, chillers, heat exchangers and water circulation systems.

The Scientific History of Corrosion: From Rust to Materials Engineering

Corrosion throughout history

The phenomenon of corrosion began at the same time as humans used metals. The first historical references to corrosion date back to the writings of the Greek philosopher Pliny about the rusting of iron weapons. However, the scientific approach to this phenomenon began only in the 18th century.

In 1824, Humphry Davy, an English scientist, first used sacrificial anodes to protect the hulls of ships. This work is considered a turning point in the transformation of corrosion from an experimental problem into a scientific branch.

Foundations of the science of corrosion are established

1830s:The British Society for the Promotion of Science begins the first systematic studies of the corrosion of iron.

1847:Richard Addy proves that corrosion is caused by an electrochemical reaction between oxygen, water, and metal.

1903:The first course entitled "Chemical Resistance of Materials" is held in America.

1922:The Massachusetts Institute of Technology (MIT) first taught corrosion on a university campus.

These developments paved the way for the emergence of corrosion engineering as a separate discipline.

Basic Corrosion Tests in the Lab

What is corrosion? A simple and scientific definition

Corrosion is a natural process in which metals react with their surroundings (such as water, oxygen, acids, or salts) over time to form more stable compounds—such as oxides or hydroxides. This process causes loss of strength, leakage, improper heating, and ultimately equipment failure.

The most common types of corrosion in industry:

1. Uniform Corrosion

- The entire surface of the metal is eroded uniformly.

- Predictable and usually controlled by protective coatings.

2. Galvanic Corrosion

- Occurs when two dissimilar metals come into contact in an electrolyte (such as water).

- The more active metal (anode) corrodes faster.

3. Crevice Corrosion

- Occurs in crevices or places where fluid flow is restricted.

- Common in flanges, gaskets, and fittings.

4. Stress Corrosion Cracking (SCC)

- A combination of mechanical stress and a corrosive environment.

- Very dangerous, as it occurs without apparent warning.

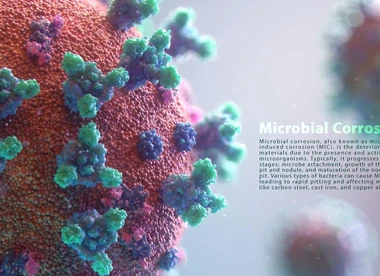

5. Microbiologically Influenced Corrosion (MIC)

- Caused by the activity of certain bacteria in water systems.

- Common in cooling towers and water transmission lines.

Why are industrial equipment particularly susceptible to corrosion?

Equipment such as boilers, chillers, heat exchangers, thermal desalination plants, and cooling towers are subject to the most severe types of corrosion due to the nature of their work—i.e., constant contact with water, steam, chemicals, and high temperatures.

Factors that exacerbate corrosion in these systems:

- The presence of dissolved oxygen in water

- Improper pH (acidity or alkalinity of water)

- High temperature that increases the rate of chemical reactions

- Inorganic deposits (such as calcium carbonate) that create under-deposit corrosion conditions

- High-velocity water flows that create erosion corrosion

Practical solutions for controlling and preventing corrosion

1. Controlling the quality of incoming water

Water is the main factor in causing corrosion in industrial systems. Therefore:

- Reducing water hardness using softeners or deionizers

- Removing dissolved oxygen with deoxygenators or anti-oxygen chemicals

- Adjusting the pH within a safe range (usually between 8.5 and 10 for boilers)

2. Using anti-corrosion chemicals (Corrosion Inhibitors)

These materials prevent direct contact between water and metal by creating a protective layer on the metal surface. Common types:

- Phosphates and silicates for hot water systems

- Amines for steam line protection

- Molybdate or nitrite additives in closed systems

Key point: The choice of anti-corrosion agent should be based on the composition of the water, the type of metal, the temperature and the pressure of the system. Improper use can have the opposite effect.

3. Regular chemical cleaning

Over time, even with the best anti-corrosion programs, deposits and corrosion layers accumulate. Chemical cleaning:

- Improves the thermal efficiency of the equipment

- Reduces energy consumption

- Extends the life of the equipment by several years

The cleaning process should include the following steps:

1. Initial inspection: Analysis of the type of deposit and corrosion

2. Selection of the appropriate chemical solution: acidic, alkaline or mixed

3. Controlled execution: Respecting temperature, time and concentration

4. Final rinsing and neutralization

5. Application of a protective coating after cleaning

Technical team performing chemical flushing of a heat exchanger

4. Periodic testing and continuous monitoring

- Testing of inlet and circulating water (weekly or monthly)

- Checking wall thickness with ultrasonic devices

- Using corrosion coupons to measure the actual corrosion rate

This data will help you take action before failure occurs.

Frequently Asked Questions (FAQ)

❓ Are corrosion inhibitors harmful to the environment?

Some old materials (such as chromates) are toxic, but today eco-friendly corrosion inhibitors based on molybdate, citrate or natural polymers have been developed.

❓ When should we perform chemical flushing?

If:

- Thermal efficiency of the system has decreased

- Fuel or electricity consumption has increased

- Abnormal outlet temperatures are observed

It is probably time for flushing.

❓ Can corrosion be stopped completely?

No — corrosion is a natural process. But with proper planning, it can be reduced to a level that is both economically and safety-wise safe.

Conclusion: Take corrosion seriously, before it takes you seriously!

Corrosion is a slow but powerful enemy. But with sufficient knowledge, regular planning, and the use of scientific solutions, you can prevent its financial, safety, and operational losses.

If you operate in industry and have equipment such as boilers, chillers, or heat exchangers, expert, test-based advice can make a difference in the life of your equipment for several years.

✅ What should you do next?

- Share this article with your colleagues.

- Establish a water quality monitoring program for your systems.

- If you need technical advice on chemical cleaning or choosing the right anti-corrosion agent, contact experienced professionals in this field.

share :

Submit your opinion

Your email address will not be published.