Industrial antifreeze and anti-boiler: A complete guide to protecting heating and cooling systems

Introduction: Why do industrial systems need antifreeze and anti-boiler?

Many engineers and maintenance workers are faced with the question:

“Can plain water be used in circulating systems?”

The short answer is: No, not without serious risks.

Plain water, even clean water, in heating and cooling systems can lead to freezing in the winter, boiling in the summer, internal corrosion of pipes, and scale formation in heat exchangers. These problems not only reduce efficiency, but can also severely reduce the useful life of equipment or even completely disable it.

Industrial antifreeze and anti-boiler agents — often referred to as “heat transfer fluids” or “industrial antifreezes” — purposefully control these risks by adding specific chemicals. In this comprehensive guide, we take a closer look at why these agents are necessary, what problems they solve, and how they can be used optimally.

Why do heating and cooling systems need antifreeze and antiboiler?

Industrial circulating systems — from boilers and chillers to cooling towers and heat exchangers — are constantly exposed to temperature fluctuations. These systems are used to transfer heat, and any malfunction can damage the entire production process.

Here, we examine four main challenges that make the use of antifreeze/antiboiler fluid necessary:

Problems of using plain water in circulating systems

Town or well water, even after simple filtration, contains ions and impurities that are dangerous for industrial systems:

- Calcium and magnesium ions: lead to the formation of scale on the internal surfaces of pipes and exchangers.

- Dissolved oxygen: the main cause of oxidative corrosion in carbon steels.

- Water hardness: reduces heat transfer and increases energy consumption.

- Microorganisms: Under the right conditions, biofilm and biological growth leads to reduced flow and contamination of the system.

Therefore, even at moderate temperatures, plain water can cause hidden damage that only becomes apparent after months or years.

Note:

The three main causes of damage in circulating systems are:

1. Extreme temperature fluctuations (freezing/boiling)

2. Internal corrosion due to oxygen and improper pH

3. Sedimentation and biofouling due to water impurities

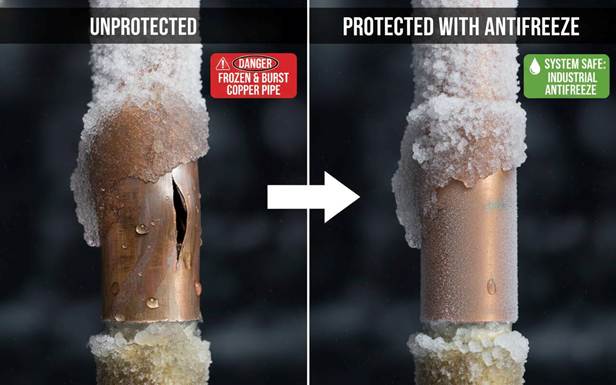

Winter freezing: dangers for pipes, packages and radiators

In cold regions or during cold seasons, the water temperature in the system can drop below 0°C. In these conditions:

- The water expands — this expansion creates pressure that can crack the pipes or tear the inner walls of the exchanger.

- The flow stops — central heating systems are no longer able to provide heat.

- The costs of emergency repairs on cold days are very high and replacement parts are not always available.

Industrial antifreeze prevents this damage by lowering the freezing point (Freezing Point Depression). Some modern compounds lower the freezing point to -40°C.

Boiling in the summer: pressure drop and damage to pumps and engine rooms

In the summer or in industrial environments with high heat loads (such as power plants, refineries or chemical plants), the temperature of the circulating fluid can exceed 100°C. Results:

- Cavitation: Steam bubbles inside the pump cause rapid wear of the impeller and reduce its service life.

- System pressure drop: Boiling causes steam to form in the flow path, which interrupts the fluid flow.

- Localized heating of the walls: leads to deformation or cracking in heat exchangers.

Anti-boiling agents control these phenomena by increasing the boiling point (Boiling Point Elevation). Advanced formulations increase the boiling point to 130°C or more.

Question:

Are antifreeze and anti-boiling agents two different substances?

No. Many modern formulations are both antifreeze and anti-boil, because they use compounds such as glycol (Ethylene or Propylene Glycol) that simultaneously lower the freezing point and raise the boiling point.

Corrosion and scale: two invisible enemies of equipment life

Even if the system is operating within a safe temperature range, two hidden threats still exist:

1. Corrosion

- Main factors: dissolved oxygen, low pH (acidic), chlorides, sulfates.

- Disadvantages: leaks in pipes, clogged valves, sensor failure.

- Exposed metals: carbon steel, copper, aluminum, stainless steel (in certain conditions).

2. Scale & Fouling

- Main factors: water hardness (⁺Ca²⁺, Mg²), silica, ferric iron.

- Disadvantages: reduced heat transfer by up to 40%, increased energy consumption, equipment overheating.

Quality industrial antifreezes contain mixes of corrosion inhibitors and scale inhibitors that manage these two problems simultaneously.

How to choose an industrial antifreeze/antiboiler?

Choosing the right antifreeze fluid is not based on “freezing point” alone. There are six key criteria:

1. Type of chemical base:

- Ethylene Glycol: High thermal efficiency, but toxic — suitable for closed industrial environments.

- Propylene Glycol: Non-toxic, safe for environments with indirect contact with food or pharmaceuticals.

2. Inhibitor formulation:

- Copper systems require triazole inhibitors.

- Aluminum systems are sensitive to high pH and require special buffering.

3. Operating temperature range:

- From –40°C to +130°C for general applications.

- For special applications (such as power plants), formulations with higher operating temperatures are available.

4. Compatibility with system materials:

- Confirmation of compatibility with rubbers, sealants, and interior plastics is essential.

5. Thermal stability and shelf life:

- Quality formulations last up to 3–5 years without chemical degradation.

6. Testability and monitoring:

- Some formulations allow for rapid testing of pH, concentration and anti-corrosion properties.

Note:

Industrial antifreeze = glycol base + corrosion inhibitor + anti-scale + pH buffer + stabilizers

Maintenance and monitoring of antifreeze/anti-boil performance

Installing a quality antifreeze is not the end of the matter. Periodic monitoring is essential:

- Every 6 months: pH test (should be between 8–10)

- Every year: Glycol concentration measurement (with refractometer)

- Every 2 years: Complete fluid replacement (or based on operating conditions)

- If discolored or cloudy: sign of chemical degradation or microbial growth — immediate replacement required

Question:

Can automotive antifreeze be used in an industrial system?

No. Automotive antifreeze lacks the necessary inhibitors for carbon steel or industrial copper and can cause severe corrosion.

The dangers of using substandard or imitation antifreeze

Many users turn to cheap products because of the cost. But:

- Imitation products lack active inhibitors → Severe corrosion after a few months

- Actual glycol concentration lower than label claims → Higher freezing point than expected

- PH imbalance → Rapid corrosion of aluminum or copper

Key point:

In an industry study, systems using substandard antifreeze were 3.2 times more likely to leak and fail. The importance of antifreeze and its applications

Conclusion: Protect your capital, not your expense

Using industrial antifreeze and anti-boiler is not an “expense”, but a smart investment to:

- Prevent production downtime

- Reduce emergency repair costs

- Increase energy efficiency

- Extend equipment life by two or three times

If your system is exposed to temperature fluctuations, or if you are still using plain water, check today whether your circulating fluid is fully protecting your equipment.

If you need expert advice to identify the type of deposit or the optimal selection of chemicals, Abrizan Company’s specialists, with more than 20 years of experience in advanced laboratories, are ready to provide customized solutions to various industries.

share :

Submit your opinion

Your email address will not be published.