Step-by-step guide to chemical boiler cleaning — professional and safe execution

Introduction: Why is Boiler Flushing a Smart Decision?

Is your heating equipment efficiency declining? Are you experiencing erratic steam pressure, increased fuel consumption, or unusual temperatures in your boiler system? Mineral deposits and corrosion layers inside your boiler pipes and tanks are likely threatening the health and efficiency of your system.

Boiler flushes not only remove these deposits, but also extend the life of your equipment and dramatically reduce energy and maintenance costs.

However, performing this process without following safety and technical standards can seriously damage equipment or even pose hazards to operators.

In this comprehensive guide, we will review all the key steps of boiler flushes, from system shutdown to final passivation, in a step-by-step and fully educational manner, while adhering to ASME standards and safety guidelines.

Industrial boiler with mineral deposits — Boiler chemical flushing to restore efficiency

Why is boiler chemical flushing necessary?

Industrial boilers are exposed to a variety of contaminants that, over time, impair their performance:

- Calcium and silica deposits: caused by water hardness, which insulate the heat transfer surface.

- Oxide and corrosion layers: reduce the thickness of metal walls and risk of perforation.

- Sulfate-reducing bacteria (SRB): create biofilms and biocorrosion.

These problems not only reduce system efficiency (up to 20% in severe cases), but also compromise operational safety.

Reference standards: ASME and safety guidelines

Compliance with international standards is essential in the correct implementation of boiler chemical flushing, especially in industrial environments. The most important reference in this field:

ASME PTC 24 – Standard for Chemical Cleaning of Power Plant Equipment

This standard provides detailed instructions for:

- Selecting the appropriate chemicals

- Flow methods (soaking cycles)

- Control of chemical parameters such as pH, temperature and contact time

- Safety and environmental steps

- Neutralization and passivation processes after cleaning

It is also vital to comply with OSHA guidelines on the use of personal protective equipment (PPE) and environmental ventilation to prevent exposure to acids or toxic vapors.

Step-by-step steps for chemical cleaning of boiler

1. Complete shutdown of the boiler system

Before any chemical intervention, ensure that:

- The boiler is completely deactivated and out of service.

- All steam and hot water are drained from all parts of the system.

- All inlet and outlet valves are closed and locked (Lockout-Tagout).

- The electrical charge in the relevant parts is disconnected.

This is the most basic step to prevent potential accidents.

2. Completely drain the system of water and existing reserves

After shutdown, all remaining water in:

- Main tank

- Return pipes

- Collectors and condensers

must be drained. The use of drain valves at the lowest points of the system is recommended.

It is important that no moisture remains in the system that could react adversely with the flushing solution.

Draining the boiler before chemical cleaning

3. Initial inspection and identification of the type of scale

Before selecting a cleaning solution, be sure to determine the type of scale by laboratory analysis. Common types of scale in boilers include:

- Calcium carbonate (CaCO₃): Caused by temporary water hardness

- Calcium sulfate (CaSO₄): More resistant to acids

- Iron oxides (Fe₂O₃, Fe₃O₄): Caused by corrosion

- Silica (SiO₂): Very hard and resistant to common acids

With this information, you can select the appropriate type of acid or chelating agent (e.g. citric acid for iron oxides, dilute hydrochloric acid for carbonates).

4. Preparation of the cleaning solution

The composition of the cleaning solution varies depending on the type of scale and the metal material of the boiler (carbon steel, stainless steel, etc.).

In general, a standard cleaning solution consists of the following components:

- Acid or main chelating agent (e.g. 2–5% citric acid)

- Corrosion inhibitor

- Surfactant to improve solution penetration

- Antifoam if desired to reduce foam production

All ingredients should be weighed carefully and dissolved in a mixing tank with cold water.

Safety tip:Never add water to acid! Always add acid to water to avoid an exothermic reaction.

5. Solution application method: Circulation or soaking?

There are two main methods for chemical cleaning:

a) Circulation

- The solution is continuously circulated through the system via circulation pumps.

- Suitable for large and complex systems.

- Provides continuous monitoring of pH, temperature and concentration.

b) Soak

- The solution is left in the boiler and is in contact for several hours (usually 4–8 hours).

- Suitable for small systems or limited access.

- The parameters are more difficult to control.

In any case, the solution temperature should be in the range of 60–80°C (except for sensitive steels where lower temperatures are recommended).

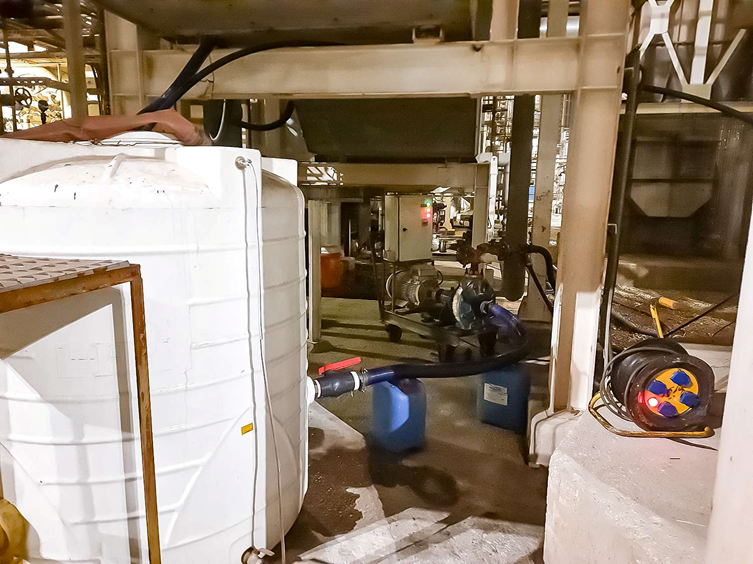

Boiler Chemical Washing Solution Circulation System

6. Continuous Monitoring of Chemical Parameters

During the washing process, continuous monitoring is necessary:

Parameter | Optimal range | Monitoring method |

pH | 2–4 (depending on acid) | pH meter or test strips |

Temperature | 60–80°C | Thermometer or temperature sensor |

Acid concentration | Gradual decrease | Periodic titration |

Solvent paint | Darkening indicates the presence of metals | Optical or spectroscopic |

Any deviation from the range requires immediate adjustment.

7. Draining the rinsing solution and initial rinsing

After the reaction time has elapsed (usually 4–8 hours):

- Slowly drain the rinsing solution.

- Rinse the system several times with cold tap water to remove any residual acid.

- The effluent water should be neutral (pH ≈ 7).

Environmental note: Acidic solutions should be neutralized in accordance with local regulations and then disposed of.

8. Chemical neutralization

Even after mechanical cleaning, acid residues may remain in crevices or porous surfaces.

To prevent further corrosion, circulate the system with a mild neutralizing solution (such as a post-scaling neutralizer) for 30–60 minutes.

9. Passivation — post-rinse protection

This is a very important but often overlooked step. After the scale layers have been removed, the bare metal surface is very susceptible to corrosion when exposed to air and moisture.

Passivation protects the surface from future oxidation by creating a thin protective oxide layer (e.g. using a descaling agent after descaling).

The passivation process typically involves:

- Descaling agent solution after descaling

- Temperature 60–70°C

- Contact time: 2–4 hours

- Followed by a final rinse with demineralized water

10. Final inspection and reporting

After completion of the process:

- Visual inspection of internal surfaces (using industrial cameras if required)

- Return water testing to confirm the absence of heavy metals

- Recording of a technical report including: type of deposit, materials used, time, temperature, pH, observations and maintenance recommendations

This report will be the basis for planning future preventive cleaning.

❓❓❓ Frequently Asked Questions (FAQ) ❓❓❓

❓ How long does a chemical cleaning of a boiler take?

Depending on the volume and type of system, it usually takes between 8 and 24 hours. This includes all steps from preparation to passivation.

❓ Can the cleaning be done without shutting down the boiler?

No. Chemical cleaning of the boiler requires the complete removal of the system from the circuit. It is dangerous and impractical to do it during operation.

❓ Does chemical cleaning damage the boiler?

If done with the right materials, corrosion inhibitors, and careful control of parameters, there is no harm—in fact, it increases the useful life of the boiler.

❓ When should we do chemical cleaning?

- 10% or more reduction in thermal efficiency

- Abnormal increase in metal temperature

- Observation of deposits in water samples

- Every year as a preventive measure

✍️ Conclusion: Chemical washing, a smart investment for the industry

Chemical washing of boilers is a technical and planned process that, by following precise steps and international standards, can:

✅ Increase system efficiency by up to 30%

✅ Reduce fuel consumption and energy costs

✅ Reduce safety risks from corrosion and uneven heating

✅ Extend equipment life by several years

If you operate in the desalination, refinery, power plant or steam generation industry, expert advice on choosing the right type of washing, chemicals and timing is the key to the success of this operation.

Do you need expert help with chemical washing of your boiler or industrial equipment? ✈️⚡✈️⚡✈️

Get in touch with the experts of our specialized laboratories so that we can design the best solution for your system by conducting detailed tests.

About Us ⭐⭐⭐⭐⭐

With over two decades of experience in the field of industrial chemistry, Abrizan Industrial Research Company produces a variety of specialized scale removers, anti-corrosion agents and oxygen scavengers for water, oil and gas systems. Our experts, by conducting detailed tests in specialized laboratories, provide customized solutions for chemical cleaning of all types of boilers, desalinators, chillers and heat exchangers and other industrial equipment.

If you need free advice on the type of cleaning or selection of the right chemicals, contact our experts so that we can help your industry.

share :

Submit your opinion

Your email address will not be published.